Electric Arc Furnace

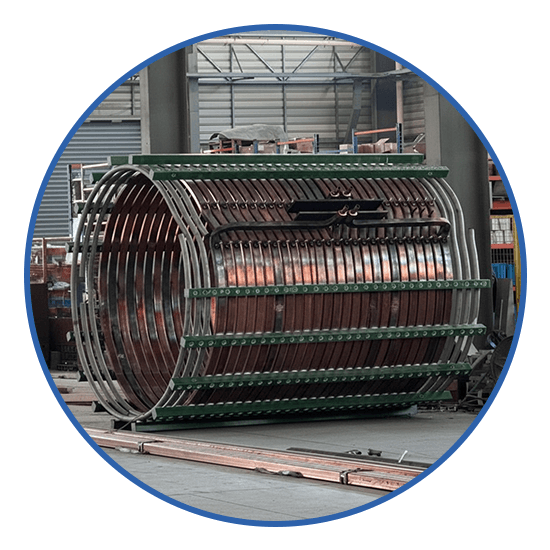

I. Position in the Metallurgical Process The Electric Arc Furnace (EAF) is the primary melting unit in modern steel plants, forming the first and most critical step in the EAF–LF–VD/VOD–CCM steelmaking route. It is responsible for converting solid metallic charge into molten steel and directly determines productivity, energy consumption, and steel cleanliness of the entire melt shop. II. Application: The EAF is used for smelting carbon steel, high quility carbon steel and various alloy steel. It applies to all syeel scrap, hot metal crap, pelletizing and preheating steel scrap. hot briquetted iron an dsponge iron, etc. III. Technical Features: High-Impedance & Long-Arc OperationThe EAF is designed with a series reactor in the main electrical loop, allowing stable long-arc, high-voltage, and low-current operation. This improves arc stability, reduces electrode consumption, and enhances overall melting efficiency. Efficient Oxygen and Burner SystemIntegrated oxygen lances and furnace wall burners accelerate scrap melting, promote foamy slag formation, and significantly shorten tap-to-tap time. Advanced Eccentric Bottom Tapping (EBT)The EBT system ensures slag-free tapping, minimizing re-oxidation and nitrogen pickup. This results in cleaner steel, lower load on the ladle furnace, and longer refractory life. Robust Water-Cooled Furnace StructureThe furnace adopts a frame-type, fully water-cooled shell with detachable upper and lower sections. This design provides excellent thermal protection, long campaign life, and stable operation under high power input. Flexible Mechanical OperationFurnace tilting, electrode lifting, and roof rotation are controlled by proportional hydraulic systems, ensuring smooth, precise, and reliable operation during charging and tapping. Automation & Process ControlThe entire EAF system is equipped with PLC and computer-based control and monitoring systems, enabling real-time process adjustment, data tracking, and safe operation. IV. Specification of Electric Arc Furnace V.Main Equipment Scope Yeneng EAF supply typically includes: Furnace shell, roof, and water-cooled panels Graphite electrode system and lifting mechanism Tilting mechanism and hydraulic system Short network interface and power-related components Oxygen injection and burner system Level 1 automation and process control system Scope can be flexibly adjusted according to project requirements and existing plant configuration. VI. Engineering Value & Operational Benefits Short tap-to-tap time and high productivity Low specific power and electrode consumption Improved steel cleanliness and stable quality Reduced maintenance frequency and long service life High adaptability to local raw materials and operating conditions VII. Why Choose Yeneng Electric Arc Furnace Xi’an Yeneng Metallurgical Engineering Co., Ltd. is an experienced supplier of EAF systems with strong engineering capabilities and full EPC service capacity. We do not only deliver equipment, but provide process-oriented furnace solutions, covering design, manufacturing, installation, commissioning, and long-term technical support. Our EAF solutions help steel producers achieve lower operating cost, higher efficiency, and stable long-term performance, making them well suited for developing and fast-growing steel markets in the Middle East and Southeast Asia. About Us Xian Yeneng Metallurgical Engineering Co., Ltd is a leading provider of advanced steelmaking solutions based in Xian, China. We specialize in the design, R&D, manufacturing, and installation of furnaces and related equipment, as well as providing comprehensive overhaul services. Our Core Products Electric Arc Furnaces (EAF) Submerged Arc Furnaces (SAF) Ladle Refining Furnaces (LRF) VOD/VAD/VD Furnace Induction Furnaces One-Stop Solution: Furnace, Spare parts, maintenance, and equipment upgrade services